What are the advantages of silicone rubber fiberglass sleeves in high-temperature environments?

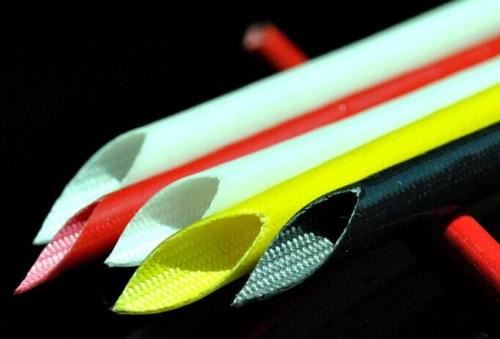

Silicone rubber fiberglass casing is made of high-purity alkali free fiberglass and coated with high-quality silicone rubber on the outer layer. It is currently a commonly used high resistance casing. What are the advantages of silicone rubber fiberglass casing in high-temperature environments?

Silicone rubber fiberglass sleeves have the following application advantages in high-temperature environments:

Heat resistance:

Silicone rubber fiberglass casing can be used for a long time within 260 ℃ due to its unique performance of raw materials, without deformation or combustion; Within 1000 ℃, withstand for 5-10 minutes; Instantaneous temperature can withstand 1700 ℃. It can be applied to protect pipeline equipment under most high-temperature conditions.

Fire retardant performance:

The rubber glass fiber sleeve is woven with high-temperature resistant glass fiber, and the surface silicone is added with appropriate flame retardant materials to ensure good flame retardant performance. It can greatly reduce the occurrence rate of fires, and even if a fire occurs, it can provide sufficient time for rescue personnel.

Thermal insulation performance:

In high-temperature workshops, there are many pipeline equipment with high temperatures. If not protected, it can easily cause heat loss and even burn workers. Silicone rubber glass fiber provides excellent insulation and internal heat radiation performance, which can prevent internal heat transfer in the workshop, provide air temperature, and increase cooling costs.

Silicone rubber fiberglass sleeves have excellent high-temperature resistance and can provide excellent protection in high-temperature environments. They can be widely used in various high-temperature environments. Erik can provide multiple high-quality silicone rubber fiberglass sleeve products. Customers in need are welcome to contact us for consultation.